The high quality Henan pneumatic lifting pump helps the Singapore baking soda powder industry to take off

In Singapore, the industrial product demand drives the industrial upgrading path by fostering innovation and technological advancements. The city-state has strategically invested in R&D to enhance productivity and efficiency in manufacturing, leveraging on its strong knowledge economy base. Collaboration with academia and industry is crucial; it fosters technology transfer, incubates startups, and accelerates the commercialization of innovative products. Additionally, Singapore's focus on high-value added sectors such as electronics, precision engineering, and biomedical technologies ensures that industries remain competitive and responsive to global trends. Lastly, environmental sustainability is a cornerstone of Singapore's industrial strategy, driving companies towards green production methods to meet international standards and consumer preferences.

Baking Soda, or sodium bicarbonate, is a common household ingredient used in cooking and cleaning. It's a white crystalline powder that neutralizes acids and promotes rising in baked goods by reacting with acids such as buttermilk, yogurt, or lemon juice to create carbon dioxide gas bubbles.

In Singapore, several businesses may face transportation challenges for baking soda due to its granular form. These challenges include ensuring the product remains dry and free from moisture during transit, preventing clumping, and maintaining product integrity throughout the supply chain process. Some companies that might experience these issues include food manufacturers who use baking soda in their recipes, catering services that prepare large batches of baked goods, and cleaning supply providers who stock the item for household use.

The logistics of transporting this substance require careful packaging and storage to prevent damage and maintain freshness. The use of airtight containers or bags is essential to keep the powder dry, which can be problematic during humid conditions common in tropical countries like Singapore. Moreover, the handling and delivery processes must adhere to safety standards to avoid any potential health hazards associated with inhaling or ingesting baking soda particles.

Ensuring efficient and safe transport of baking soda is vital for these businesses to deliver quality products to their customers without disruption caused by logistical setbacks.

Dynamic Sealing Technology Innovations: New Pathways for Leakage Control in Baking Soda Powder Conveying Systems

In the realm of industrial conveying systems, particularly those handling dry powders like baking soda (sodium bicarbonate), leakage control remains a significant challenge. Traditional static sealing methods have proven insufficient to address the complex dynamics of powder flow and the wear that can lead to leaks. However, recent innovations in dynamic sealing technology offer a promising solution to this problem.

The heart of these new approaches lies in the application of dynamic seals that employ rotating elements designed to adapt to the varying pressures and material flows encountered in conveying systems. Unlike static seals which rely on fixed clearances or gaskets that can deteriorate over time, dynamic seals actively respond to changes in system conditions, thus maintaining an effective barrier against leakage.

One key advancement involves using specialized materials that are both durable and resistant to the abrasive nature of dry powders. These materials are often composites that can withstand the high friction and stress levels associated with continuous operation. Additionally, these materials are designed to minimize the risk of material build-up, a common cause of blockages and subsequent leaks.

Another breakthrough is the integration of sensors that continually monitor the sealing interface. These sensors provide real-time feedback on seal performance, allowing for early detection of potential failure points. This information can then be used to adjust the seal's operational parameters, ensuring a consistently tight fit without compromising equipment integrity.

In summary, by leveraging advanced materials and incorporating smart sensor technology, dynamic sealing innovations offer a new frontier in controlling leakage from conveying systems handling substances like baking soda powder. This not only enhances process efficiency but also promotes a safer work environment while reducing waste and contamination. It represents a crucial step forward in meeting the demands of industries that require precision and reliability in their material transfer operations.

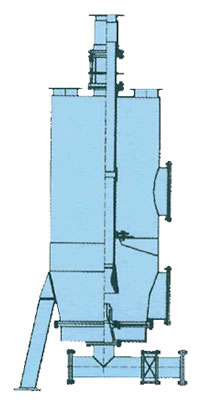

Overall, improving the environmental management of baking soda in Singapore is an important task that requires the optimization of processes, the adoption of advanced equipment and technology, and strict control at various stages. At the same time, enhancing the technical content of pneumatic lifting pumps is also a key part of the environmental management of baking soda. Only by solving these problems can we truly improve the efficiency of environmentally friendly transportation of baking soda, promote industrial development, meet customer needs, fulfill our mission, work together, and move forward hand in hand into the future! Join us as we extend our best wishes to ZHONGYUAN customers in Singapore for pneumatic lifting pumps: every word is a bond of communication, weaving understanding and trust