Quality Excellent Henan Brand Twin Shaft Humidifying Mixer Deeply Excavates the Potential of Timor Leste Calcium Powder Industry

In the era of digital economy, Timor-Leste is actively pursuing global leading technology products. This pursuit is driven by the country's desire to modernize its infrastructure and enhance its economic competitiveness. By embracing cutting-edge technology, such as artificial intelligence, automation, and renewable energy solutions, Timor-Leste aims to improve efficiency in various sectors, including agriculture, healthcare, and education. The government recognizes the potential of technology to spur innovation, create jobs, and ultimately uplift the living standards of its citizens. As a result, Timor-Leste is investing in research and development and seeking partnerships with international tech companies to ensure that it remains at the forefront of technological advancements in the digital age.

East Timor, a small island nation nestled between Asia and Australia, is experiencing an economic surge due to the rise of its calcium powder industry. This industry's ascendancy has been propelled by a combination of natural resources and strategic market positioning.

East Timor's calcium powder production is largely derived from its abundant limestone deposits. The quality and purity of these minerals have attracted international investors, leading to significant investments in infrastructure and technology. The country's strategic location, offering easy access to both regional and global markets, further enhances its attractiveness as a calcium powder supplier.

The government, recognizing the potential of this industry, has implemented policies aimed at fostering growth. These include tax incentives for foreign investment, research and development subsidies, and export promotion schemes. Additionally, East Timor has focused on environmental sustainability, ensuring that calcium powder extraction and processing adhere to strict international standards.

As a result of these concerted efforts, East Timor is now a key player in the global calcium powder market. Its products are utilized across various industries, including construction, agriculture, and manufacturing. With a robust supply chain and a commitment to innovation, East Timor's calcium powder industry is poised for continued success and expansion.

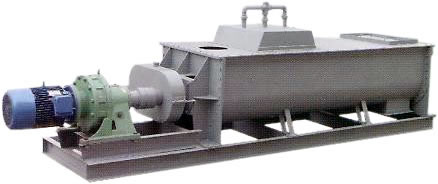

Title: Design of an Automated Control System for Dual-Shaft Humidifying Mixer in Calcium Powder Transportation

Abstract: This document presents the design of an automated control system for a dual-shaft humidifying mixer, specifically tailored to efficiently handle calcium powder transportation. The system integrates sensors, actuators, and advanced software to ensure precise control over humidity levels, blending uniformity, and material flow rates. The automation aims to enhance safety, reduce human error, and maintain product quality consistently. The design focuses on scalability, reliability, and ease of maintenance for diverse industrial applications involving calcium powder handling.

Introduction: The increasing demand for controlled humidity environments in industries has necessitated the development of advanced automation solutions. This paper details the design considerations for a dual-shaft humidifying mixer control system designed to meet these challenges. Our focus is on calcium powder, which requires careful handling due to its hygroscopic nature. The automation system will integrate real-time monitoring, feedback loops, and adaptive controls to optimize the mixing process while ensuring product quality.

System Components: The core components of the system include high-precision humidity sensors, variable speed drives for the dual shafts, pneumatic actuators for door operations, and a programmable logic controller (PLC) as the central processing unit. The PLC communicates with a user interface (UI) for manual adjustments and displays real-time data from various sensors. The UI provides visual cues and alerts to operators, facilitating informed decisions.

Control Logic: The control logic is based on a modular design approach, allowing for easy expansion or modification. It incorporates algorithms for predictive humidity control and dynamic feed rate adjustment to maintain a consistent output. Safety protocols are embedded within the logic to prevent hazardous conditions like overheating or equipment overload. The system also includes self-diagnostics and preventive maintenance schedules to extend the life of the machinery.

Conclusion: The automation control system for the dual-shaft humidifying mixer offers a comprehensive solution for managing calcium powder transportation processes. Its design prioritizes efficiency, reliability, and safety while maintaining product consistency. With its ability to adapt to varying operational conditions, this control system promises to be a valuable asset in diverse industrial settings requiring humidity control and material blending.

Overall the application of twin shaft humidifying mixer in the short distance transportation industry of calcium powder in Timor Leste is of great significance. It can not only improve the production efficiency and quality of calcium powder related enterprises reduce production costs but also promote the development of the industry. However there are also some problems in the application of twin shaft humidifying mixer in the calcium powder transportation industry which need further research and solution. In the future with the progress of technology the performance of twin shaft humidifying mixer will be further improved and its application in the calcium powder industry will be more extensive. Seize the day live up to your prime time! Working hand in hand we wish ZHONGYUAN customers of twin shaft humidifying mixer in Timor Leste a wider path of cooperation and a brighter future.