Reputable Henan Pneumatic Lift Pump Supports Indonesian Kaolin Industry Leap

Indonesia is known for its robust agricultural sector, which plays a significant role in the country's economy. The nation is self-sufficient in food production and is one of the world's largest exporters of commodities such as palm oil, rubber, and coffee. Agriculture employs a large portion of the Indonesian workforce, with rice being the staple crop. Additionally, fisheries are an important component of Indonesia's food security strategy, as it is among the top producers and exporters of fish globally.

In terms of industry, Indonesia has been making strides in diversifying its economy beyond the natural resources sector. Manufacturing has seen growth in recent years, particularly in the processing industries like textiles, footwear, automotive parts, and electronics. Jakarta, the capital city, is a hub for financial services, while other regions specialize in different industrial sectors such as mining and energy, including the extraction of coal and natural gas. The government has been promoting domestic manufacturing to reduce reliance on imports and improve the country's export competitiveness.

In Indonesia, the production of kaolin (high-grade kaolinite clay) is an important industry. The country boasts several key enterprises that specialize in the mining and processing of kaolin. These companies have adopted advanced technologies to ensure efficient and dust-free transportation of the material from extraction sites to processing facilities.

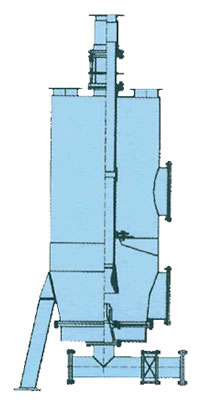

The most notable approach used by these Indonesian producers involves the use of pneumatic conveying systems. These systems utilize pressurized air to move dry granular materials like kaolin through a closed pipe network. This method minimizes exposure to external elements, such as humidity or airborne contaminants, which can affect the quality of the kaolin.

Another common technology employed is vacuum conveying. With this process, a vacuum is created in a sealed pipeline to draw the kaolin particles through the system without the need for moving parts. This approach also ensures minimal dust emission, as it operates under a controlled environment.

Both pneumatic and vacuum conveying systems are designed to prevent product degradation and maintain the purity of kaolin. They offer precise control over the flow rate and can be easily integrated with other processing equipment to create a seamless operation.

Indonesian manufacturers have invested heavily in automation and monitoring technologies to optimize their kaolin handling operations. This includes sensors that monitor the integrity of the conveying systems and automatic controls that adjust pressure and flow rates accordingly, ensuring continuous and reliable material transfer.

By adopting these sophisticated conveying techniques, Indonesian kaolin producers not only improve their operational efficiency but also contribute to environmental protection by reducing the release of fine particulates into the atmosphere. This commitment to sustainable practices is becoming increasingly important in the global market for high-quality kaolin products.

To enhance the sealing performance of a pneumatic boosting pump and reduce leakage of kaolin, consider the following measures:

1. **Seal Maintenance and Lubrication**: Regularly inspect seals for wear or damage. Ensure that all seals are lubricated with a suitable sealant to prevent dry friction which can lead to premature failure.

2. **Pressure and Temperature Monitoring**: Monitor the operational pressure and temperature closely. Excessive pressure or temperature can cause seals to expand or degrade, leading to leaks. Adjust operating parameters as necessary.

3. **Regularly Replace Seals**: Implement a schedule to replace seals at predetermined intervals before they reach the end of their serviceable life. This proactive approach prevents leaks caused by worn-out seals.

4. **Improved Seal Design**: Consider using high-performance seals such as mechanical seals that have better resistance to heat and chemicals, reducing the likelihood of leaks.

5. **Leak Detection Systems**: Install leak detection systems to quickly identify any breaches in the sealing system. Early detection allows for prompt action to be taken, limiting the extent of kaolin loss.

6. **Operator Training**: Ensure operators are properly trained on the correct handling of the pneumatic boosting pump. Incorrect operation could stress seals beyond their design limits.

7. **Clean Environment**: Maintain a clean environment around the pump to prevent foreign objects from entering the seal area, which could cause damage and leaks.

8. **Quality Control**: Enforce strict quality control measures during the manufacturing process of the pump and its components to ensure the integrity of the seals is met.

By implementing these measures, you can significantly improve the sealing performance of your pneumatic boosting pump, thereby reducing kaolin leakage and preserving product quality.

Overall Indonesia as a region with rapid economic development has a huge production of kaolin How to effectively process and utilize this kaolin is not only related to the operational efficiency of kaolin related enterprises but also to environmental protection In this regard pneumatic lift pumps as an efficient and environmentally friendly kaolin transportation equipment have broad application prospects in kaolin related enterprises In the future we look forward to seeing more technological innovations and product optimizations to meet the needs of kaolin processing and utilization in Indonesia and other domestic and foreign regions while also making greater contributions to environmental protection Stepping forward with determination and chasing dreams with perseverance Together with you we wish ZHONGYUAN Indonesia pneumatic lift pump customers Thank you for fighting alongside us creating one glorious achievement after another