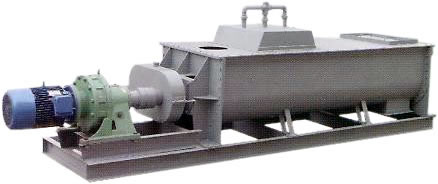

Top Quality Henan Made Dual Shaft Humidifying Mixer Boosts the Development of Diatomite Industry in Poland

The evolution of the Polish labor market, viewed through the lens of industrial product demand in English, reflects significant shifts. A surge in technical and engineering roles is evident, driven by a burgeoning need for skilled workers to handle sophisticated machinery and equipment. This shift is particularly pronounced in sectors such as automotive manufacturing and electronics assembly, where proficiency in English is crucial for accessing international markets. Additionally, an increasing focus on quality assurance and customer service has led to a demand for bilingual personnel with strong communication skills. These changes have not only reshaped the workforce but also prompted ongoing training and education initiatives to meet the evolving needs of the industry.

The design and optimization of the dust-free conveying system for polandish diatomite are critical to ensure efficient and environmentally friendly material handling. The system's efficiency is enhanced through a series of innovative measures, such as the use of high-quality sealing elements that minimize dust leakage. These seals effectively control the flow of diatomite particles and maintain a clean, controlled environment within the conveying line.

Furthermore, the system's components have been meticulously selected to withstand the abrasiveness of diatomite while ensuring smooth operation. This includes using robust materials for the screw conveyor, which transfers the diatomite without causing wear or damage.

In terms of optimization, the system's design has been optimized by reducing unnecessary parts and simplifying structures where possible. This not only enhances operational reliability but also contributes to cost savings in both manufacturing and maintenance.

Overall, the dust-free conveying system for polandish diatomite represents a significant advancement in the field, offering a balance between functionality and cost-effectiveness, thereby setting a new benchmark for similar applications.

Title: Energy Consumption Analysis and Energy-Saving Measures for Twin-Shaft Humidification Mixer in a Diatomaceous Earth Conveying System

In the diatomaceous earth conveying system, energy consumption plays a crucial role in maintaining efficiency. The twin-shaft humidification mixer is one of the key components that require careful analysis to identify areas for improvement.

The energy consumption of the twin-shaft mixer can be attributed to various factors such as the motor power, gearbox efficiency, and friction losses due to operation. To optimize these factors, several measures can be taken. Firstly, using variable-frequency drives (VFDs) can adjust motor speed based on demand, reducing unnecessary energy use when lower throughputs are required. Secondly, regular maintenance and greasing of the mechanical parts can minimize friction loss, leading to smoother operations and reduced energy consumption. Thirdly, implementing an automated monitoring system to track and record operational data allows for better control over the process and enables adjustments to be made promptly when necessary, thus preventing energy waste.

Moreover, utilizing high-efficiency motors and upgrading the gearbox with low-friction bearings can further enhance energy efficiency. Finally, conducting a comprehensive energy audit to assess the mixer's performance can reveal additional opportunities for energy saving.

In conclusion, by focusing on the optimization of motor and mechanical components, along with the implementation of advanced monitoring systems and regular maintenance practices, considerable energy savings can be achieved within the diatomaceous earth conveying system, especially in the operation of the twin-shaft humidification mixer.

In summary the market prospects of diatomaceous earth twinshaft humidifier mixers in Poland are filled with opportunities and challenges For twinshaft humidifier mixer enterprises it is necessary to seize the growth opportunities of market demand while also preparing for technological and managerial innovations in twinshaft humidifier mixers For the government it is essential to create favorable environmental conditions for business development while remaining sensitive and responsive to changes in the policy environment Only in this way can the continuous development and prosperity of Polands diatomaceous earth environmental transport technology and twinshaft humidifier mixers be promoted Focusing on craftsmanship sincere service creating exceptional quality Working together ZHONGYUAN wishes Polish twinshaft humidifier mixer customers Communication is not only an exchange of words but also a collision of souls Let us achieve mutual benefits in cooperation and share the joy of success