ZHONGYUAN Helps Greek Force Boost Pump Customers to Reduce Costs and Increase Efficiency

To secure a foothold in the global industrial product demand, Greek companies must focus on innovation and quality. They should invest in research and development to create unique products that cater to niche markets. Collaboration with other businesses for joint ventures or partnerships can help expand their reach and resources. Marketing and brand awareness are crucial; therefore, investing in digital marketing strategies to target international buyers is essential. Greek manufacturers must also prioritize sustainability and ethical production practices to align with global trends. By continuously improving these aspects, Greek industries can carve out a competitive position in the worldwide industrial product market.

The expansion of production capacity at the Greek soda ash plant poses significant challenges for dust-free conveying systems. With increasing production scales, the demand for efficient and robust conveying solutions intensifies to ensure seamless material transfer without compromising on environmental standards or worker safety.

One challenge is maintaining high efficiency in the conveying process as the throughput increases. Traditional conveying methods may struggle to keep up with the larger volumes, necessitating the use of advanced technologies like pneumatic conveying or mechanical conveying systems capable of handling bulk materials over extended distances with minimal energy consumption.

Another concern relates to dust control. As the plant expands, more attention must be given to containment measures that prevent airborne dust particles from escaping into the surrounding environment. This requires careful design and operation of the conveying system, possibly incorporating dust collection and suppression technologies.

Furthermore, scalability is a critical factor. The conveying systems must be designed to allow for future upgrades and expansions without substantial overhauls, thus ensuring long-term investment protection and operational flexibility.

Lastly, the reliability and maintenance of the conveying systems become paramount. High-capacity operations require equipment that is both durable and easy to maintain, reducing downtime and improving overall productivity.

In conclusion, as the Greek soda ash production scale grows, so does the complexity and sophistication required of its conveying systems. By embracing cutting-edge technologies, focusing on dust management, and prioritizing scalable and reliable designs, these challenges can be effectively met, paving the way for an efficient and environmentally conscious production facility.

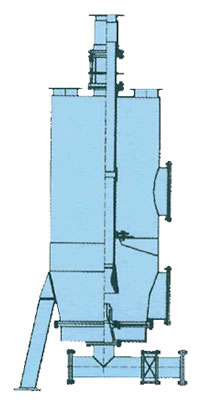

In the transportation of sodium carbonate, pneumatic conveying pumps play a pivotal role. These devices utilize air as a medium to lift and transfer the powdered material from one location to another. The efficiency and reliability of these pumps significantly impact the overall productivity and safety of the conveying process.

The value of pneumatic conveying pumps in sodium carbonate transport lies in their ability to handle high volumes with minimal loss of product due to their gentle handling mechanism. This minimizes damage and contamination, preserving the integrity of the chemical compound, ensuring consistent quality for further processing or packaging.

Moreover, they are designed to handle abrasive materials like sodium carbonate, reducing wear on machinery parts and extending equipment lifespan, thus lowering maintenance costs. Their flexibility allows them to work within varying operational conditions, such as different pipeline lengths and inclinations, enhancing their applicability in various industrial settings.

In conclusion, pneumatic conveying pumps are essential in maintaining a smooth and cost-effective sodium carbonate supply chain. They facilitate the efficient movement of this vital commodity while minimizing operational risks and maximizing product quality.

In summary, the market prospects for sodium carbonate pneumatic lifting pumps in Greece are filled with opportunities and challenges. For enterprises in the pneumatic lifting pump industry, it is essential to seize the growth opportunities presented by market demand while also preparing for innovations in technology and management of pneumatic lifting pumps. For the government, it is crucial to create favorable environmental conditions for business development and remain sensitive and responsive to changes in the policy environment. Only in this way can we promote the continuous development and prosperity of environmentally friendly transportation technology for sodium carbonate and pneumatic lifting pumps in Greece. Craftsmanship builds quality, focus achieves greatness! Working together, ZHONGYUAN wishes Greek pneumatic lifting pump customers: Thank you for your support and trust. Let us cooperate closely to create a bright future together, wishing everyone success in their endeavors.