Lithuanian customers for the pneumatic booster pump take a look ZHONGYUAN helps kaolin transportation industry reduce costs and increase efficiency

The Impact of Global Industrial Product Demand Changes on the Lithuanian Economy

Global industrial product demand plays a significant role in the economic landscape of Lithuania. As the world economy shifts and consumer demands evolve, these changes are reflected in the export and import patterns of countries like Lithuania. When global demand for industrial goods increases, it typically leads to an upswing in Lithuania's exports, as their products become more sought after in international markets. This increased export activity can boost the country's GDP, create jobs in manufacturing sectors, and increase government revenues through taxes on businesses and individuals.

Conversely, declines in global industrial product demand can lead to decreased exports for Lithuania. Such a scenario may result in job losses, reduced company profits, and lower government revenues, potentially affecting public spending and investment in infrastructure and social services. The diversification of Lithuania's export base is crucial in mitigating these risks; by not relying too heavily on one sector or type of product, the economy becomes more resilient to fluctuations in global demand.

In conclusion, global industrial product demand changes directly impact Lithuania's economy through variations in export earnings and employment rates. To sustain economic growth and stability, Lithuania must adapt its industrial strategy to align with global trends while also promoting economic diversity.

Lithuanian Kaolin Dust-Free Conveying Technology and Its Role in Assuring Product Quality

The utilization of Lithuanian kaolin, a high-quality clay material known for its whiteness and purity, is pivotal in various industrial applications. The process of handling and conveying kaolin demands meticulous attention to prevent any contamination or degradation that might affect the final product quality. This is where dust-free conveying technology plays a crucial role.

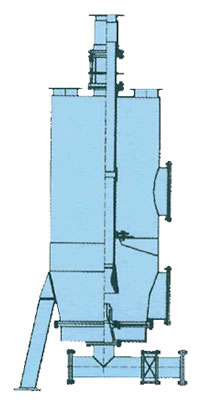

Dust-free conveying systems employ advanced engineering solutions to transport kaolin without generating airborne particles. These systems feature sealed pipelines, vacuum or pneumatic methods, and specialized equipment designed to contain the kaolin within the system's boundaries. Such technology significantly reduces the risk of cross-contamination with other materials, environmental exposure to atmospheric conditions (like humidity or temperature changes), and worker exposure to potentially hazardous dust.

By maintaining a controlled environment throughout the conveyance process, the integrity of kaolin is preserved, ensuring it arrives at the point of processing or packaging in its original, pristine state. The absence of airborne contaminants minimizes the need for further cleaning or purification stages, thus reducing costs and improving productivity.

In summary, the implementation of Lithuanian kaolin's dust-free conveying technology not only enhances the safety and health of the working environment but also serves as a fundamental quality assurance measure by preventing any form of contamination during the transfer of this delicate material. It's a testament to the commitment towards producing high-quality end products that meet the stringent standards of the industry.

In the transportation of kaolin, pneumatic conveying pumps are utilized due to their efficiency and ability to handle powders and slurries. Different models of these pumps offer unique performance characteristics, which can significantly affect the overall process.

The rotary lobe pump is a common type used for gentle handling of kaolin. It features two lobes that rotate inside a housing, gently mixing and moving the material with minimal shear. This reduces the risk of product damage, making it suitable for delicate applications.

Centrifugal pumps, on the other hand, use centrifugal force to move the kaolin through a system. They can handle larger volumes of material but may not be as gentle as rotary lobe pumps, potentially causing more particle damage.

Diaphragm pumps offer pulsating flow, which could lead to segregation if the kaolin has different particle sizes or densities. However, they're often preferred in situations where airtightness and metering are critical.

Screw conveyors utilize a rotating helical screw within a tubular enclosure to convey dry materials. While effective for certain kaolin applications, they might not handle wetter materials well due to potential clogging.

Air-operated double diaphragm (AODD) pumps provide robust and reliable operation, especially when handling high viscosity kaolin slurries. Their simplicity and self-priming capabilities make them a popular choice for demanding conditions.

Comparatively, peristaltic hose pumps move the kaolin by squeezing a flexible hose with an eccentric wheel or crankshaft mechanism. They are known for their ability to control flow rate accurately and have a low shear rate, protecting the integrity of the kaolin particles.

Each pump model offers its own set of benefits and drawbacks for kaolin conveying. The selection should consider factors such as the consistency and purity requirements of the kaolin, the system's pressure and flow requirements, and the environmental conditions of the operation.

In summary the market prospects of Lithuania's kaolin pneumatic lifting pump are full of opportunities and challenges. For pneumatic lifting pump enterprises it is necessary to seize the growth opportunities of market demand while also preparing for technological and managerial innovations in pneumatic lifting pumps. For the government it is essential to create favorable environmental conditions for enterprise development while also being sensitive and responsive to changes in the policy environment. Only in this way can we promote the continuous development and prosperity of Lithuania's kaolin environmental protection conveying technology and pneumatic lifting pumps. Working together for mutual benefit and development! Joining hands with ZHONGYUAN we wish the customers of Lithuania's pneumatic lifting pumps a heartfelt thank you for your unwavering support. In the days to come we will hold ourselves to higher standards strive for cooperation and wish our customers a colorful life and thriving careers.