The Henan brand pneumatic booster pump with excellent craftsmanship helps Qatar's soda ash industry move forward

The gross domestic product (GDP) of Qatar is one of the highest in the world, largely due to its vast oil and natural gas reserves. As of my last update, Qatar's GDP per capita was estimated at over $68,000, ranking it among the top countries globally in terms of wealth per citizen. This impressive figure reflects a robust economy that has been significantly bolstered by its energy exports, which account for a significant portion of the country's total revenue and export earnings.

Sodium carbonate, commonly known as soda ash, is an inorganic compound with the molecular formula Na2CO3. It is a white, water-soluble crystalline substance that has a wide range of applications due to its basic properties. Sodium carbonate is produced industrially by the Solvay process or the ammonia-soda process, which involves the reaction of sodium chloride with ammonia and carbon dioxide to produce sodium bicarbonate and then heating it to obtain sodium carbonate along with water and carbon dioxide as byproducts. Sodium carbonate is used extensively in the production of glass, detergents, and soaps, as a pH regulator in industrial processes, and in the textile industry for the processing of wool and silk fabrics. It is also employed in the paper industry, water treatment, and various chemical synthesis processes.

The Impact of Sodium Carbonate (Na_2CO_3) Characteristics on the Performance of Pneumatic Conveying Systems

Sodium carbonate, also known as soda ash or washing soda, is a white, crystalline powder that has various industrial and household applications. Its chemical formula is Na_2CO_3, and it belongs to the class of alkaline substances. When discussing its influence on pneumatic conveying systems, one must consider several properties that can affect the efficiency and reliability of the system.

Firstly, sodium carbonate's particle size distribution plays a significant role in the conveying process. Smaller particles have a larger surface area per unit mass, which increases their tendency to adhere to pipe walls and reduce flow rates. Conversely, larger particles may be less prone to sticking but are more challenging to handle due to their higher weight and propensity for segregation. An optimal particle size balance needs to be maintained to ensure efficient conveying without compromising the integrity of the system.

Secondly, the hygroscopicity of sodium carbonate should not be overlooked. Sodium carbonate has a moderate affinity for moisture, which can lead to caking and clumping within the pipeline. This phenomenon can result in blockages and reduced flow rates, necessitating frequent system cleaning and maintenance. Therefore, maintaining a dry environment during storage and transportation is essential.

Another consideration is the temperature at which the sodium carbonate is being conveyed. High temperatures can accelerate chemical reactions, potentially causing degradation of the material or equipment. Moreover, elevated temperatures can lead to increased viscosity of the conveyed air, reducing the conveying capacity. Appropriate insulation and temperature control measures are crucial in managing this aspect.

Lastly, the purity of the sodium carbonate can impact the performance of the pneumatic conveying system. Impurities such as dust, organic matter, or other salts can alter the physical and chemical properties of the material, leading to unpredictable behavior within the system. It is therefore vital to source high-purity grades of sodium carbonate to ensure consistent conveying performance.

In conclusion, understanding the specific characteristics of sodium carbonate, such as particle size distribution, hygroscopicity, temperature sensitivity, and purity level, is crucial when designing and operating a pneumatic conveying system for this material. By carefully considering these factors, engineers can mitigate potential issues and optimize the overall performance of the conveying system.

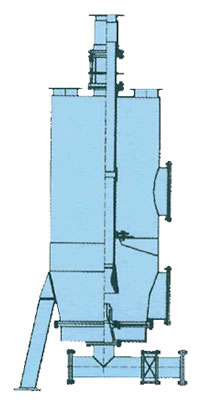

In summary, Qatar's soda ash pneumatic lifting pump market is full of opportunities and challenges. For pneumatic lifting pump companies, it is necessary to seize the growth opportunities in market demand while also preparing for technological and management innovations in pneumatic lifting pumps. For the government, it is essential to create favorable environmental conditions for enterprise development while remaining sensitive and responsive to changes in the policy environment. Only in this way can we promote the continuous development and prosperity of Qatar's soda ash environmentally friendly conveying technology and pneumatic lifting pumps. Focus on professionalism, craftsmanship creates quality products! Join hands with us, ZHONGYUAN wishes Qatar pneumatic lifting pump customers: communication is not just about exchanging information, but also about understanding each other's needs and expectations, making our cooperation smoother and achieving mutual success in the future.