Word of mouth Henan brand pneumatic booster pump helps Cambodian gypsum powder industry move forward

# Global Industrial Product Procurement Strategies under the Rise of Cambodia's Economy

## 1. Understanding Cambodia's Economic Landscape

Cambodia has been experiencing robust economic growth, driven by factors such as a young and growing population, increasing foreign investment, and a focus on key industries like garment manufacturing, tourism, and agriculture. This rise presents new opportunities for global industrial product procurement.

## 2. Identifying Key Industries for Procurement

### Garment and Textile Industry

- With its established reputation in garment manufacturing, Cambodia offers a wide range of textile products. Procurement strategies should focus on quality control, ensuring compliance with international standards, and establishing long-term partnerships with reliable suppliers.

- Exploring value-added products such as finished garments with higher design and craftsmanship can enhance competitiveness in the global market.

### Agro-Processing Industry

- Cambodia's abundant agricultural resources present opportunities for procuring processed food products. Emphasis should be on sourcing sustainable and organic ingredients, implementing stringent food safety measures, and supporting local farmers to ensure a stable supply chain.

### Electronics Manufacturing

- The country is gradually developing its electronics industry. Procurement strategies should involve assessing the capabilities of local manufacturers, investing in technology transfer and training, and collaborating with them to produce cost-effective electronic components and devices.

## 3. Considerations for Procurement Strategies

### Quality Assurance

- Implement rigorous quality control systems throughout the procurement process, from raw material selection to final product inspection. This includes conducting regular factory audits and working closely with suppliers to address any quality issues promptly.

### Cost Efficiency

- While Cambodia offers relatively lower production costs compared to some other countries, it is essential to balance cost with quality. Negotiating favorable terms with suppliers, optimizing logistics, and reducing lead times can help achieve cost efficiency without compromising on product standards.

### Sustainability and Social Responsibility

- Given the growing importance of sustainability and ethical practices, procurement strategies should prioritize suppliers that adhere to environmental and labor regulations. This not only ensures responsible sourcing but also enhances brand reputation in the global market.

### Supply Chain Resilience

- Diversify the supplier base to mitigate risks associated with supply chain disruptions. Building strong relationships with multiple suppliers in Cambodia and other regions can provide flexibility and stability in meeting global demand.

## 4. Leveraging Technology and Innovation

### Digital Procurement Platforms

- Utilize digital platforms to streamline the procurement process, improve transparency, and enhance communication with suppliers. These platforms can facilitate real-time tracking of orders, inventory management, and data analysis for better decision-making.

### Research and Development Collaboration

- Engage in collaborations with local research institutions and universities to drive innovation in product development. This can lead to the creation of unique and differentiated products that meet the evolving needs of the global market.

## 5. Conclusion

The rise of Cambodia's economy opens up exciting prospects for global industrial product procurement. By understanding the country's economic landscape, identifying key industries, considering important factors in procurement strategies, and leveraging technology and innovation, businesses can tap into the potential of Cambodia's growing industrial sector and gain a competitive edge in the global market.

以下是翻译内容:

**Which Equipment Has Low Cost for Gypsum Powder Conveying?**

When it comes to conveying gypsum powder, several types of equipment can be considered in terms of cost. Here are some common ones and their cost analysis:

### Belt Conveyors

- **Description**: They use a continuous belt to transport materials. The belt moves over rollers, carrying the gypsum powder from one place to another.

- **Cost Advantage**: Generally, belt conveyors have a relatively low initial investment compared to some other equipment. The components are not as complex, making manufacturing and maintenance costs more affordable. For example, a simple belt conveyor system may only require the purchase of a belt, motor, and some supporting structures, which can be obtained at a reasonable price.

- **Limitations**: However, they may not be suitable for long distances or high throughput requirements. The belt can also wear out over time, especially when handling abrasive materials like gypsum powder, which may increase maintenance costs in the long run.

### Screw Conveyors

- **Description**: These conveyors use a rotating screw blade to move materials along a trough. The gypsum powder is pushed forward by the rotation of the screw.

- **Cost Advantage**: Screw conveyors are usually cost-effective for short to medium distance transportation. They have a simple design with fewer parts, resulting in lower manufacturing and maintenance costs. In addition, they can handle a variety of materials, including gypsum powder, and are relatively easy to install.

- **Limitations**: But they may not be efficient for very large volumes of material or long conveying distances. The screw can also get clogged if the material is not fed evenly, which may affect the overall efficiency and increase maintenance work.

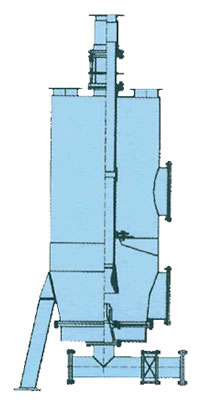

### Pneumatic Conveying Systems

- **Description**: This method uses air flow to transport gypsum powder through pipes. There are different types, such as vacuum pneumatic conveying and pressure pneumatic conveying.

- **Cost Advantage**: Pneumatic conveying systems can be efficient for long distances and can handle large volumes of material. They also offer a clean and dust-free operation, which is beneficial for the working environment. In some cases, the initial investment may be higher, but the long-term operational costs can be lower due to reduced labor and maintenance requirements.

- **Limitations**: However, the installation and commissioning of pneumatic conveying systems can be complex and expensive. They also require a reliable source of air and proper filtration systems to ensure the quality of the air and the efficiency of the conveying process.

In summary, the choice of equipment with the lowest cost for gypsum powder conveying depends on various factors such as the distance to be covered, the volume of material to be handled, and the specific requirements of the application. Belt conveyors and screw conveyors may be more cost-effective for short distances and lower throughput, while pneumatic conveying systems can be a better option for longer distances and higher volumes, despite their higher initial investment.

# The Wear Mechanism and Protection Measures of Gypsum Powder Conveying by Pneumatic Boost Pump

## I. Wear Mechanism

### 1. Abrasive Wear

Gypsum powder particles, with certain hardness and angularity, act as abrasives. When conveyed by the pneumatic boost pump, they continuously rub against the inner wall of the pipeline and the surface of the boost pump components. Over time, this friction gradually removes material from the contact surfaces, leading to wear.

### 2. Erosion Wear

The high-speed airflow in the pneumatic boost pump system carries gypsum powder particles. These particles, when accelerated by the airflow, impact the inner wall of the pipeline and the components of the boost pump. The repeated impacts cause a gradual loss of material from the impacted surfaces, resulting in erosion wear.

### 3. Adhesive Wear

Under certain conditions, such as temperature and humidity changes, gypsum powder may adhere to the inner wall of the pipeline or the surface of the boost pump components. When the boost pump operates, the relative movement between the adhesive layer and the base material causes shearing forces, which can tear off small pieces of material from the base, leading to adhesive wear.

## II. Protection Measures

### 1. Material Selection

Choose materials with high hardness and good wear resistance for the inner wall of the pipeline and the components of the boost pump. For example, ceramics, stainless steel, or wear-resistant alloys can be used to enhance the wear resistance of the equipment.

### 2. Surface Treatment

Apply wear-resistant coatings on the inner wall of the pipeline and the surface of the boost pump components. Common coatings include ceramic coatings, polymer coatings, and metal spraying coatings. These coatings can form a protective layer on the surface, reducing the direct contact between gypsum powder and the base material, thereby improving the wear resistance of the equipment.

### 3. Optimize System Design

Optimize the design of the pneumatic boost pump system, such as adjusting the flow rate and pressure of the airflow, reducing the impact force of gypsum powder particles on the inner wall of the pipeline and the components of the boost pump. Additionally, reasonable design of the pipeline layout can reduce the occurrence of turbulence and eddy currents, further reducing wear.

In summary, the market prospects for gypsum powder pneumatic lifting pumps in Cambodia are filled with opportunities and challenges. For companies manufacturing pneumatic lifting pumps, it is essential to seize the growth opportunities in market demand while also preparing for technological and managerial innovations in pneumatic lifting pumps. For the government, it is necessary to create favorable environmental conditions for enterprise development and remain sensitive and responsive to changes in the policy environment. Only in this way can we promote the continuous development and prosperity of environmentally friendly transportation technology for gypsum powder and pneumatic lifting pumps in Cambodia. After thousands of adjustments and tens of thousands of refinements, achieving satisfaction a hundred times over and ensuring peace of mind tenfold! Working together, ZHONGYUAN wishes the best for customers of pneumatic lifting pumps in Cambodia: We sincerely appreciate the cooperative spirit of our customers who transport gypsum powder with pneumatic lifting pumps, and we wish everyone a life filled with sunshine and laughter.